A track segment is a stretch of track, such as a single curve or tangent section, that is evaluated and/or ground as a unit. Any stretch of track for which you wish to create a grinding plan record with the grinding system must be a track segment. A track segment is identified by track, start mile and end mile.

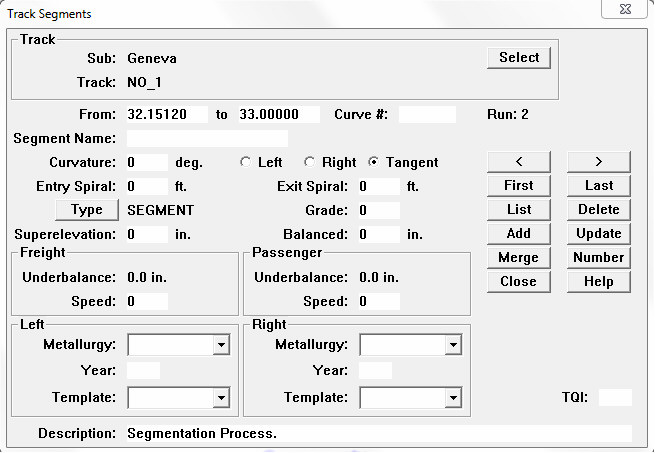

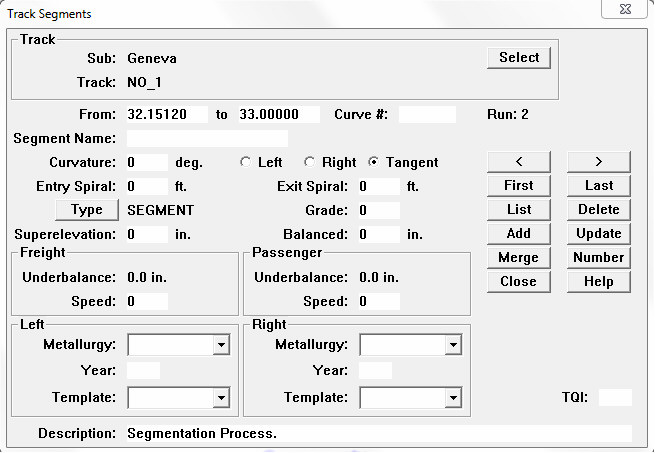

After clicking on the Track Segment menu item the program proposes to select a track if it was not selected previously. After that the Track Segments dialog opens.

The From and To fields are the start and end locations of the segment in scaled distance units. Updates to segment location behave in much the same way as updates to the track location table. That is, neighboring records are affected; segments may be merged or split.

The Merge button gives you the additional option of joining this segment to the segment immediately following it. If you do, all other attributes of the segment currently displayed are applied to the combined segment.

The Curve # field contains an optional "curve number," which may be any sequence of digits and alphabetic characters. Curves may be numbered automatically by use of the Number button. You specify a curve number value, and all subsequent curves over a specified degree of curvature are automatically numbered in ascending sequence.

If a non-zero value is entered for Curvature, then Left or Right must be specified. By convention, a left curve is one that appears to curve to the left when you face the subdivision's direction of increasing mileage.

The Type button allows you to choose a mandatory segment type from among the values specified in the Segment Type table.

The metallurgical quality of each rail may be entered, if known. The drop-down list box allows you to choose between STANDARD, PREMIUM and blank; or you may type in a different value. If you use a custom rail classification macro (see Classification Options), it may use the value of this field to distinguish between different grades of steel.

Another optional value is the year the rail was laid. This is referenced by the Wear Trend Chart and Wear Trend Report. In calculating a trend, the software excludes values for data collection runs earlier than July of the year in which the rail was laid. (The trending software also automatically excludes all runs prior to a run that shows at least 10% less wear than its predecessor. It is assumed that, in this case, the rail was changed out.)

If rail grinding templates have been recorded for the track segment, they are displayed here and may be updated. Grinding templates are used by Rangecam Grind Analyst.

Values for superelevation, balanced elevation, grade, freight speed and passenger speed are also optional. The Track Segment Query uses these values to select curves for performance analysis.

The amount of detail recorded in track segments is up to you. Compound curves may be entered separately, or combined. Some railroads record spirals as separate segments, using an average curvature value. Other options are to include spirals in the curve segment, or in the neighboring tangent sections. Since wear rates in spirals are often significantly greater than in tangent, the latter option is not recommended. If you intend to use a different grinding strategy for the body and spiral of a curve, they must be recorded as separate segments.