If the database contains imported geometry detail data, you may run the Curve Segmentation process to calculate or re-calculate track segment boundaries, spirals, degree of curvature, and related attributes including balance elevation for curves.

To run the process for a specific run, use Run/Geometry/Segment Curves... on the Profile View menu.

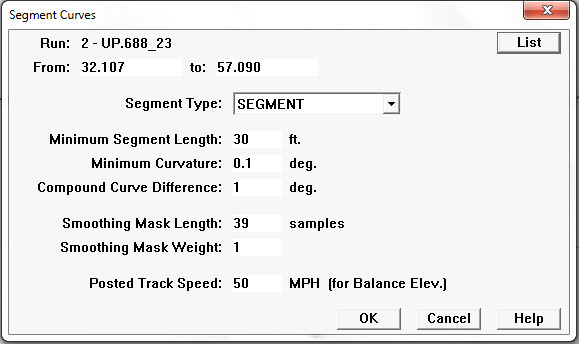

This is the Segment Curves dialog:

The Segment Curves dialog

The List button lets you choose a run for processing. Range options allow you to select the entire run, or a mileage range.

To segment curves for several runs, use Run/Calculate All....

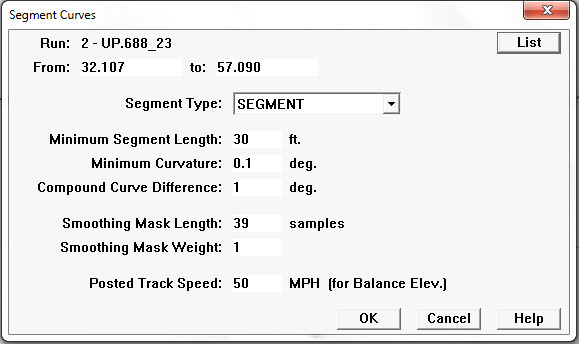

This is the Curve Segmentation Options dialog from the Run/Calculate All menu:

Note that this option allows you select individual or all runs, but does not include a mileage range.

A segment type must be associated with the track segments created by the segmentation process. In this case, the type is simply called "SEGMENT", but this field can be used to distinguish between jointed track and CWR, or to record other track attributes. If nothing appears in this drop-down list, go to Database/Track Segments/Segment Types and enter at least one segment type before proceeding.

Minimum Segment Length is the length of the shortest track segment the process will produce. Shorter segments (usually tangent) are absorbed into the curves on either side.

Minimum Curvature is the minimum curvature, in degrees, that will be recognized as a curve by the segmentation process. Sections of track with lower curvature will be classified as tangent. This value is normally set in the range 0.25 - 1.0 degrees.

Compound Curve Difference is the minimum difference in curvature between adjacent segments of a true compound curve. Segments differing by a smaller amount will be combined as one segment.

Smoothing Mask Length and Weight are used to "smooth" the curvature data for segmentation. Noise and small aberrations must be eliminated prior to processing.

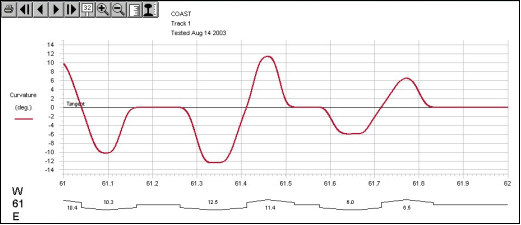

Default smoothing settings are Length = 39, Weight = 1. These settings should be used if your curvature data, as it appears in strip charts, is smooth to the eye and does not contain small bumps and dips.

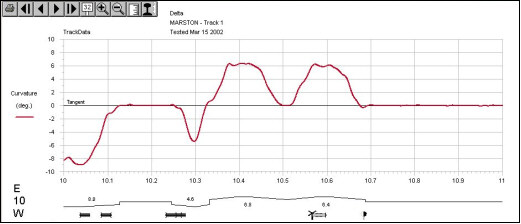

Default settings were used to segment this smooth curvature data

If the curvature data is rough, more aggressive smoothing - obtained by increasing the mask weight and, if necessary, the length - will be required. The next picture shows curvature that required a mask length of 99 and strength of 10.

Extra smoothing was required to segment this rougher curvature data

You will know more smoothing is needed if the segmentation process produces many short compound curve segments that are "not real" - at least, not by engineering design. It is preferable to increase the mask strength first, and the length only if necessary to remove longer wavelength noise. A longer mask will tend to increase the length of curve segments and decrease the length of tangents. A mask length greater than 99 should be avoided if possible.

Posted Track Speed is used to calculate the balance elevation for curves in the territory.

After you run the segmentation process, you can view the results using the Track Condition Chart, through the Database/Track Segments dialog, or in reports.

Important. Re-calculation of track segments over-writes any track segments previously recorded for the territory! It will also delete any previously-calculated average wear values for those track segments. If you use the Segment Curves function, be sure to re-calculate average wear afterwards for all runs in the territory. If you do not, features that use wear averages, such as the Trend Chart and Rail Replacement Forecast, will not work!